Product name: Elevator Category 6 double-shielded integrated power cable

Application range: Suitable for network communication, video surveillance system and signal transmission and equipment power supply of elevator control system in elevator car, which can effectively prevent electromagnetic interference in elevator shaft, ensure stable signal transmission and normal operation of equipment.

Technical parameters

Electrical performance

Transmission rate: Support high-speed data transmission of 1000Mbps and above, meeting the needs of network applications such as Gigabit Ethernet.

Conductor resistance: No more than 12.5Ω per kilometer, ensuring low loss during signal transmission.

Insulation resistance: Under DC 500V conditions, the insulation resistance is not less than 5000MΩ・km, ensuring good electrical insulation performance.

Withstand voltage strength: Can withstand AC 1500V/5min withstand voltage test, no breakdown or flashover phenomenon, ensuring safety and reliability under normal working voltage and certain overvoltage conditions.

Transmission characteristics

Near-end crosstalk: At 100MHz, the near-end crosstalk loss is not less than 30dB, effectively reducing signal interference between adjacent line pairs.

Attenuation: At 100MHz, the attenuation per 100 meters is no more than 20dB, ensuring the strength and quality of the signal during long-distance transmission.

Return loss: At 100MHz, the return loss is no less than 10dB, reducing signal reflection and improving transmission efficiency.

Power performance

Specifications of power core wire: Usually 2-core or multi-core power wires are used, and the cross-sectional area of the core is determined according to the actual power supply requirements, such as the common 1.0mm², 1.5mm², etc., which can meet the power supply requirements of monitoring equipment and communication equipment in the elevator.

Rated voltage: Generally 300/500V or 450/750V, suitable for different elevator electrical systems.

Rated current: According to the specifications and materials of the power core, its rated current carrying capacity is determined. For example, for a 1.0mm² power cord, the rated current is generally around 10A.

Physical properties

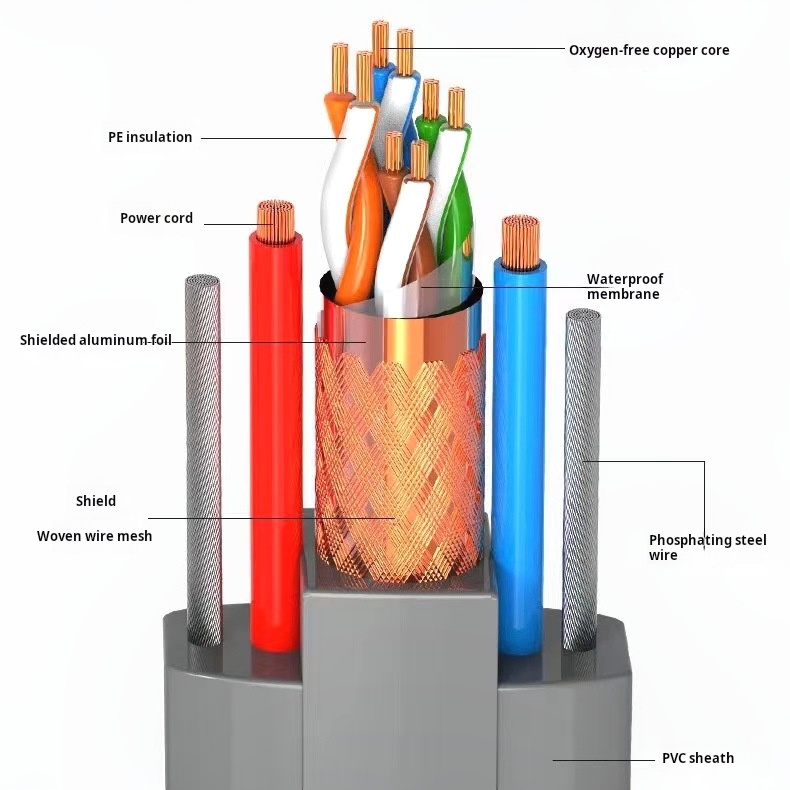

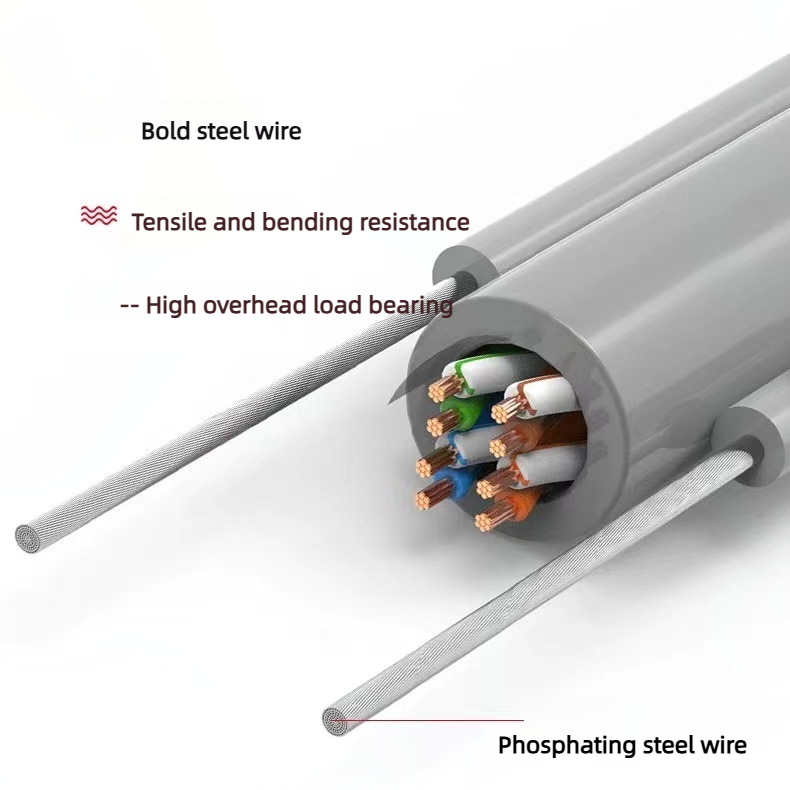

Conductor: It uses first-class oxygen-free bare copper wire, which meets the VDE0295 CLASS 5 standard. It is made of multiple fine copper wires twisted together, such as 7/0.2 structure, which ensures that the core is not easy to break during mobile installation, and has good conductivity and flexibility.

Insulation material: HDPE, PE mixture or special mixed PVC insulation material, which has good insulation performance, mechanical strength and environmental resistance, ensuring that the signal is not interfered with by the outside world during transmission.

Shielding structure: It uses anti-oxidation tinned copper braided shielding, with a shielding density greater than 95%, plus 99% aluminum foil shielding. The double-layer shielding structure can effectively prevent electromagnetic interference in the elevator shaft, avoid data packet loss and signal distortion.

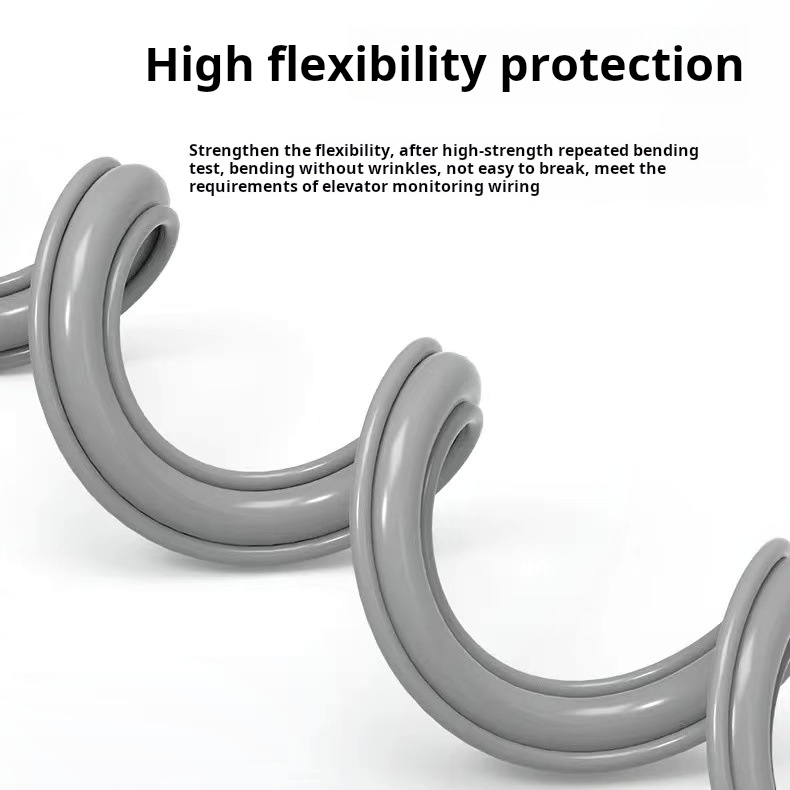

Sheath material: Elevator-specific mixed PVC material or cold-resistant PVC special sheath, which has the characteristics of wear resistance, oil resistance, bending resistance, aging resistance, UV radiation resistance, etc. It can adapt to the harsh environment in the elevator shaft and extend the service life of the cable. The sheath color is usually gray or black, and can also be customized according to customer requirements.

Reinforcement: With two high-strength galvanized steel wires, the tensile strength and tensile resistance of the cable are enhanced. It can be used in long-distance suspension applications to ensure that the cable will not be damaged by its own weight and stretching during elevator operation.

Dimensions and weight

Dimensions: The cable is flat as a whole, which is convenient for installation and laying in the elevator shaft and reduces space occupation. Its width and thickness vary according to the number and specifications of the wire cores, such as the common width of about 20mm and the thickness of about 5mm.

Weight: The weight of each meter of cable varies according to its specifications and length, generally between 0.2kg/m and 0.5kg/m.

Environmental characteristics

Working temperature: When installed mobile, the temperature range is generally – 25℃~+70℃; when installed fixedly, the temperature range is generally – 30℃~+70℃. It can work normally in a wide temperature range and adapt to different seasons and environmental conditions.

Storage temperature: Within the storage temperature range of – 40℃~+80℃, the performance of the cable will not be significantly affected, which is convenient for long-term storage and standby.

Relative humidity: In an environment with a relative humidity of 5%~95%, the cable should be able to work normally, and will not experience performance degradation or damage due to a humid or dry environment.

Radiation resistance: It has a certain radiation resistance, such as being able to withstand a radiation dose of 80Mrad {80×10⁶cJ/Kg}, which can resist the influence of electromagnetic radiation sources that may exist in the elevator shaft to a certain extent.

Safety and certification

Flame retardant performance: The cable meets the relevant flame retardant standards, such as passing the single vertical combustion test in the GB/T 18380.3 standard. The flame spreads slowly during combustion, and less smoke and harmful gases are generated. It has good fire resistance, ensuring that when a fire occurs in the elevator shaft, it will not aggravate the spread of the fire and produce a large amount of toxic smoke, thereby ensuring the safety of personnel and equipment.

Environmental requirements: Comply with environmental standards such as the RoHS directive, do not contain harmful substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and their ethers, and are harmless to the environment and human health.

Product certification: Pass relevant certifications such as CCC certification to prove that the product meets national standards and industry specifications, has reliable quality, and can be safely used in elevators and other related fields.

oxygen-free copper T-FTP6E elevator cable with wire cable

Elevator Category 6 double-shielded power integrated cable is mainly used in the following scenarios

Elevator internal communication system: network communication, voice communication

Elevator video monitoring system: real-time monitoring, video storage and playback

Elevator control system: signal transmission, equipment power supply

Other special scenarios: hospital elevator intelligent elevator system

Reviews

There are no reviews yet.